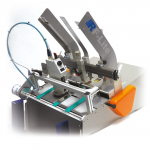

Bottle-Matic Label Applicator

This table top labelling system is deal for applying single pressure-sensitive labels to cylindrical objects like bottles and cans. These are perfect for small craft brewery or vineyard labelling applications.

The Bottle-Matic label applicators are available in 10″-wide and 16″-wide models that fit most products. The unit is fully adjustable so you can label objects from 0.5″ to 10″ diameter; ideal for everything from test tubes to 1.5-gallon bottles.

Bottle-Matic Label Applicators

Bottle-Matic bottle labellers enable you to label all kinds of cylindrical objects by simply inserting the container and depressing a footswitch. Labels are applied at over 4.5″ per second – most water bottles are labelled in less than two seconds. The operator then removes the bottle and inserts another to start the procedure again. After a rhythm is established bottles can labelled very quickly.

The Bottle-Matic comes in two sizes: Standard 10″ wide and the larger 16″ wide version for taller products. Both can handle products up to 10″ in diameter.

• Label objects from 0.5″ to 10″ diameter; ideal for all round containers from water bottles to paint jars and cosmetics.

- Accurate: Maintains 0.0625″ side-to-side accuracy on most containers.

- Labels cylinders to 15″ in length (or longer if the item has a neck).

- Able to handle most tapered containers by simply adjusting the idle roller position.

- Labels over 1000 pieces per hour with average dexterity.

- Side frames are laser cut from quality steel, then formed, countersunk, deburred and inspected.

- Dispensing tables are formed out of 6061-T6 aluminium. Its peel edge is hand- milled to spec within .001″.

- Dispensing tables are polished with ultra-fine polishing compound so paper flows freely around the plate.

- Bottle-Matic uses dual AC-shaded pole gear motors.

- Micro-switch activated; will work on all kinds of labels.

- Modifications are available for those hard-to-label containers.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

bottle-maticTouch-Screen Label Print Station

Weber’s Elo Touch-Screen Print Station provides a compact, simple solution to selecting various label formats and then printing them using Weber label printer-applicators or tabletop label printers in virtually any production environment.

The Print Station is a stand-alone computer that allows you to set-up a control station for your labelling system that features a user-friendly touch-screen for easy operation by your personnel.

View ProductManual Label Dispensers

Manual Roll Dispensers MB Series: The essential dispenser for larger rolls of self adhesive labels where low volume application is required.

View ProductXB4Jet/XB8Jet

The compact and robust controllers XB4JET and XB8JET are used to control the inkjet printheads for product marking solutions. The following Markoprint printing technologies are supported: Hewlett-Packard, Funai, Trident.

View ProductRF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

View Product