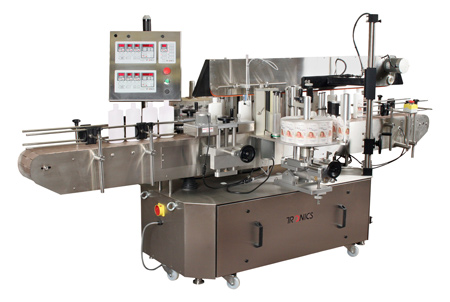

High-Speed Pressure-Sensitve Label Applicators

The Series 3 is available in standard-, medium- and high-speed models. The systems apply front, back, wrap-around, top and bottom labels for the broad range of packaging markets – and for an even wider range of products and packages. These ruggedly constructed, dependable systems can be configured to handle a diverse selection of package shapes and sizes. And the Series 3 can dispense and apply pressure-sensitive labels from .5 inch high and long to a full 10 inches high and 39 inches long.

Tronics Series 3 Label Applicator

For in-line speed and precision, the Tronics Series 3 from Weber is a system that addresses a wide variety of pressure-sensitive labeling applications. Whether you use it for a wrap-around label on a sauce bottle or a front and back combination on a shampoo bottle, the Tronics can reliably handle your product line labeling needs.

- Unmatched product and package labeling flexibility

- Labels the front, back, wrap, top, bottom – anywhere

- Applies up to 2400 inches of labels per minute

- Effortless label production set-up and quick changeover

Package Flexibility

All Series 3 label applicators are equipped with a standard 4.5-inch wide (wider widths available), 10-foot long heavy-duty conveyor and labeling heads that will accommodate up to a 9-inch wide label web (kits for larger labels are optional).

- Product sizes – from vials as small as 5ml to 10-gallon pails

- Product shapes – round, flat-sided, oval/contoured, plus unstable products like syringes, narrow cylinders/tubes, caps and more

- Product materials – plastics, paper products, metals, glass, rubber, ceramic, wood and more

Label Flexibility

The Series 3 handles small labels and large, in varying shapes, and applies them to virtually anywhere on a product or package.

- Label size – from .5-inch high by .5-inch long, up to 10 inches high by 39 inches long

- Label application – front; back; top; bottom; wrap-around (up to 100 per cent); booklet; crescent-shaped (for tapered rounds); one label on two, three or four panels; corner-wrap; two adjacent sides; spot; tamper evident; neck; one, two or three labels on a round product; RFID and more

- Label materials – standard pressure-sensitive paper, clear, Mylar, foil and more.

Product & Label Changeovers

Series 3 labeling systems are extremely user-friendly and easy to adjust when changing products and/or labels.

Conveyor rails plus modules like labeling head(s), wrap-around belt, backing pad, overhead product hold-down and aligning chains all have tool-less adjustments, in addition to quick-reference rulers beveled into the shafts. These design functions provide reference points that ease system operation.

In addition, the Series 3 features simple electronics and touch-pad controls that provide a number of unique advantages.

- On-the-fly adjustments – any label head or module can be adjusted without stopping the system; the touch-pad provides the operator with adjustment options

- Job memory – up to 100 jobs can be stored in the system’s memory to expedite changeovers

- Durability – the system’s sealed interface provides protection in chemical and other industrial environments

- On-board software – the Series 3 communicates with all popular PLCs, including Allen-Bradley and Omron.

- All software for any possible upgrade or option is pre-loaded; no downloading of proprietary software is required

Tronics Series 3 labeling systems from Weber also include an array of miscellaneous features, including batch counting, real-time products-per-minute display, total products labeled, additional inputs and outputs for missing/low label and for integration with PLCs on other packaging and handling equipment.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Tronics_Series_3_ApplicatorAlpha TIJ – Label dispenser Alpha with multifunctional inkjet-printer

The Alpha TIJ comprises a label dispenser of the proven and renowned Alpha series and a thermal inkjet printer.

View Product

Legi-Air 5300 Tyre Label Printer-Applicator

According to an EU regulation all new tires produced in or after January 2012 and placed on the market within the EU must bear a standardized EU sticker, such as those already seen on washing machines and refrigerators. The new label must contain precise details with seven grades (A-G) of fuel efficiency, wet grip, and exterior noise when in motion (in dB), respectively.

View ProductRF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

View ProductBottle-Matic Label Applicators

Bottle-Matic bottle labelers enable you to label all kinds of products by simply inserting the container and depressing a foot-switch. Labels are applied at over 4.5” per second – most water bottles are labeled in less than two seconds. The operator then removes the bottle and inserts another to start the procedure again. These automated labeling systems make it easy to label wine bottles, craft beer bottles, water bottles and most other round products.

View Product