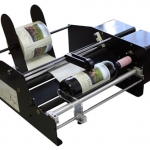

Weber 121 Wrap-Around Label Applicator

Weber’s versatile 121 provides a simple, cost-effective solution to low-volume wrap-around labelling that is as accurate and flexible as similar labelling systems used in larger-scale operations. This labelling system features the fast and accurate positioning of full, overlap and partial-wraps of pressure-sensitive labels on cylindrical containers.

Products up to 7″ in diameter and up to 12″ high easily can be accommodated using the system’s adjustable guide rails. It can handle labels up to 6 inches tall and 12 inches long and apply them at rates up to 45 products per minute to a variety of sized products. During application, labels are peeled away from the liner and securely attached to products using the wipe-on label applicator and a wrap station.

The brand-new Weber 121 system features a cost-efficient Alpha Compact labelling system mated with a wrap conveyor for a compact, easy-to-use solution for labelling bottles and other round straight-walled products. This heavy-duty wrap-labeller can be inserted into your production line to give you consistent end-to-end labelling and better control over your production.

Applies label up to 6″ high x 12″ long

Stand-alone or add to a production line

Placement accuracy of 0.03″

If you are looking for a reliable, economical bottle-wrap labelling system that is easy to set up and simple to maintain then check out the Weber 121. Industries that use the Model 121:

Craft beer labelling

Medical and pharmaceutical container labelling

Food/Sauce bottle labelling

Cylindrical beverage & juice bottle labelling

Products are delivered to the Weber 121’s built-in Alpha Compact applicator head via a 7.75″-wide, 45″-long belt conveyor, which permits product transfers at both the entry and discharge ends. The unit is capable of a superb placement accuracy of 0.03″. The Weber 121 can be integrated into existing production processes or operate as a manually fed, stand-alone solution. The unit also boasts robust steel construction that makes it ideal for lower-volume, intermittent labelling projects or for multiple-shift operations.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Geset 121 Instructions ManualGeset 121 Computer Assisted Design

EasyGo! PriceCheck

Summary

Let your customers check on the fly the price of products they are buying at your store. Improve customer satisfaction and customer experience with this self-service application. Designed for a wall-mounted device, your customers are able to check the price, get product information, and even get a picture of the product they are buying just by reading the product’s barcode. So, no matter where in the store your customers might be, help is never more than a few steps away with EasyGo!PriceCheck.

View ProductMedical Device Labels

High standards and dedicated inspection for quality assurance. Medical device labels require strict quality control during every step of the manufacturing process. On-press and post-press video inspection guarantees finished labels that meet your requirements.

View ProductBottle-Matic II Dual Label Applicator

The Bottle-Matic II goes one step further by applying front and back pressure-sensitive labels to cylindrical objects. This makes it easy, for example, to label round containers with an eye-catching decorative label on the front and a nutrition/ingredients label on the back.

The Bottle-Matic II is available in 10″-wide and 16″-wide models that fit most products. Options include a waster rewinder that collects the label liner as it is used and a large roll adapter so you can work longer between label roll change-overs.

View ProductWeber LA4050B-ES – All Electric Swing Arm System

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

View Product