It is important that Barcodes are printed correctly in order to remain readable. As soon as individual heating elements of thermal transfer and direct thermal printers fail or become dirty, it can happen that barcodes are printed incorrectly . Barcode scanners that check the codes immediately after printing can detect this immediately. But what if there is no scanner? We’ll teach you some tricks on how to check the print quality of barcodes without a scanner.

The immediate recognition of failures depends on the printing direction. Here you can differentiate between picket fence and ladder barcodes . With picket fence barcodes, the defects are not easily recognizable because of the print direction, but at a glance with ladder barcodes.

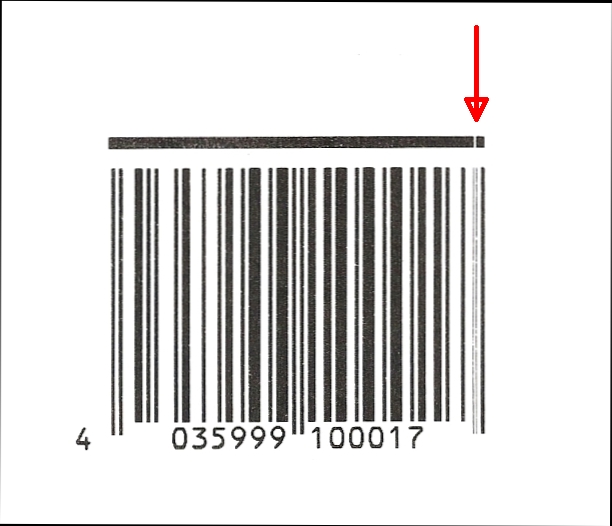

Picket fence barcodes

In the following example, it is not safe to say that the barcode on the right margin is printed correctly:

Here’s a little trick: If you install a bearer bar above the barcode, you can see from this line with the naked eye and without a scanner immediately, if the lines of the barcode are printed correctly on the entire width of the code:

Immediately you can see that a line is broken or dirty.

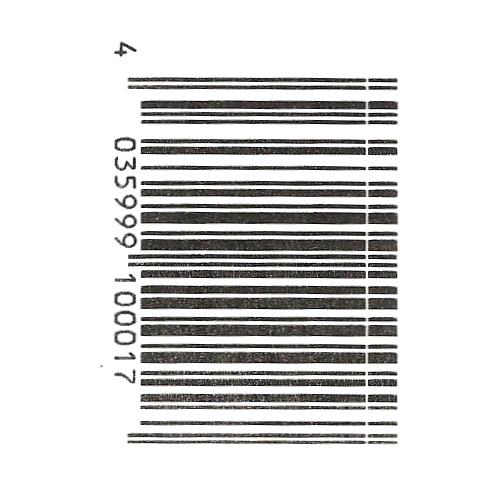

Check of ladder barcodes

The error check is simpler if the bar code is rotated by 90 °. The print defect is clearly visible as it runs vertically through the barcode

In order to maximise print quality it is imperative that the correct Label Material and Thermal Ribbon combination is used for the specific Labelling Application.

Contact our sales team for a Barcode Quality Audit https://www.weber.co.uk/about-us/direct-sales/