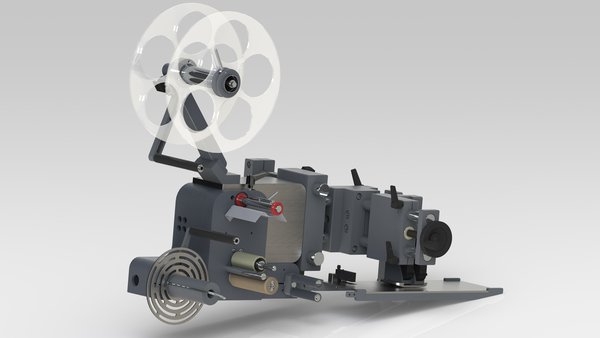

Alpha TIJ – Label dispenser Alpha with multifunctional inkjet-printer

The Alpha TIJ comprises a label dispenser of the proven and renowned Alpha series and a thermal inkjet printer.

With the Alpha TIJ variable information is printed without physical contact onto possibly pre-printed labels immediately before dispensing. No labels are wasted/lost when print data changes and previous data are automatically excluded when the product changes. Using the cartridge ink technology, labels with up to 50 mm high symbols and a resolution of up to 600 dpi can be printed neatly and quickly. Data transmission to the print heads is 1:1.

More Information:

The Alpha TIJ comprises a label dispenser of the proven and renowned Alpha series and a thermal inkjet printer. Real time printing without batch processing is also possible. A wide variety of quick drying inks and colors is available for a wide range of applications on diverse label surfaces.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

EasyGo! TicketValidate

Summary

Validate and control the authenticity of the tickets sold on site with this straight-forward yet powerful application. Check Theater, cinema, and sport event tickets… virtually any kind of ticket containing a barcode can easily be checked with this app. Combining this app with another app from EasyGo!, EasyGo! TicketsSale offers an entirely ticket validation cycle; sell-print-scan-validate tickets.

View ProductNAUTIZ X3

POCKET SIZED POWERHOUSE

It’s not one thing that makes the Nautiz X3® a breakthrough in handheld technology – it’s the unbeatable combination of small size, big performance, extreme ruggedness and remarkable value. The Nautiz X3 is like nothing else on the market.

View ProductWeber LA 6000 Labelling System

High Performance Labelling System for Warehouse & Logistics

Modularity, High Performance necessary for Warehouse and Logistics System Solutions

View ProductGeset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View Product