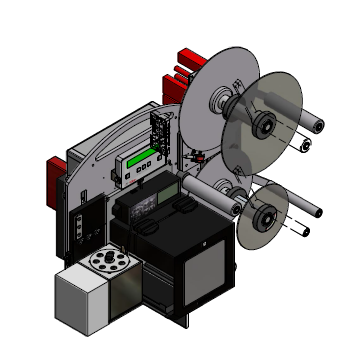

Weber LA4050BB – Blow Box High Speed Printer Applicator

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

The Weber LA4050B BB (Blow Box) is an efficient High Speed Printing and Label Application System being a High throughput alternative to some traditional pneumatic Tamp Blow Labelling Systems. Traditionally used in High Speed Mailing Solutions the Blow Box System is capable of Printing and Application throughput in excess of 250 labels per minute. The LA4050B BB is predominantly used in the application of pressure sensitive labels on the top and sides of delicate or fragile substrates without making any contact unlike Direct Tamp Systems. The system is designed for use with a variety of Print Engines such as Sato, Zebra, Datamax etc. from 203dpi to 600dpi Printing Resolutions. Typically used for Top and Side Labelling the Weber LA4050B BB can be used in a variety of Industries from Logistics to Mailing and High Speed Packaging Systems.

Like all Weber Labelling Systems the unit is modular in design with easy to remove unwinder, rewinder, and Print Engine in the event of a critical component failure. This provides significant benefits for 24/7 operation where  downtime is a cost critical factor. The choice of Print Engines add to the versatility of the System and provides label size ranges from 50mm x 40mm to

downtime is a cost critical factor. The choice of Print Engines add to the versatility of the System and provides label size ranges from 50mm x 40mm to

100mm x 100mm at a speed of up to 250 labels per minute. The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The all new Weber controller can manage the functions of the Labelling System with ease and simple to use touchscreen GUI.

The system has a pivoting U-Arm which allows rotation of the system by 360 degrees allowing the Labelling System to Print and Apply a label to any side of a product including Base Labelling of Products. The system can be mounted on its own individual stand, integrated directly into a packaging machine as part of an automated packaging line or mounted directly on one of our many handling systems providing a turn key solution to your particular Labelling requirements.

Other Benefits include:

- Low Total Cost of Ownership

- High accuracy Labelling

- Versatility and Flexibility in Labelling Configuration

- Easily adaptable to changes in Production

- Low Running Costs

- RFID Upgradeable

- High Throughput 24 / 7 Operation

- Available in 4″ wide and 6″ Wide Print Widths

- UK Service and Support Network

Additional Options include:

- Low label Warning System

- Protective Enclosure for Harsh Environments

- Barcode Scanning Module

- RFID Print Engine

- Vision System

- Choice of Product Detection Sensors

- Bespoke Handling Systems available

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

LPA_TIN_063D_LA_4050B_BB_GBX4Jet Plus

With the new high performance Markoprint X4JET print controller, different inkjet printing technologies can be controlled either simultaneously or alternately. The intuitive input unit of the new high performance Markoprint X4JET plus print controller is a boost to operator convenience. All system parameters can be entered easily and quickly, to be stored and called up later.

View ProductAxicon PV-1000 Portable Barcode Verification

The PV-1000 Portable display and collection unit has been introduced in response to the requests of our customers, who appreciate the ease of use and high level of repeatable accuracy of the Axicon PC and Mac-based verifiers, but would like to add portability to their quality processes. For existing Axicon verifier customers who now

find that portability would be beneficial in their quality control there is no need to purchase a new verifier – just add a portable display and collection unit to work with the existing equipment – the Axicon PV-1000.

OEM Auto Parts Labels

Product ID labels on your OEM auto parts have to last the life of the product. And more than likely, that will be a long, tough life cycle. Weber can help you pick the right materials to ensure that your labels continue to work through all kinds of weather and harsh conditions. OEM labels need to retain readability for technical and installation information as well as keeping the products brand image in front of the consumer.

View ProductMarkoprint Integra Vivid

Unleash the Power of Modern Touch Operating Technology and an Innovative Swipe User Interface. Say Goodbye to Complicated Print Jobs and Say Hello to Effortless Operation of X1JET and PP Class Printing Systems. With the Freedom to Position the 7” High-Resolution HMI Color Display Anywhere You Choose, Prepare to Be Awed by the Ultimate Printing Flexibility and Innovation. Upgrade to integra Vivid Today and Embrace a New Era of Printing Excellence.

View Product