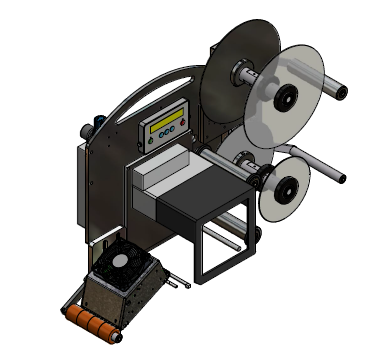

Weber LA4050B-EB – All Electric Belt Applicator System

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

The Weber LA4050B EB (Electric Belt) Provides a cost effective and efficient means of Printing and Label Application in one Sequence providing up to a 35% increase in throughput when compared to some traditional pneumatic Tamp Blow Labelling Systems. The Electric Belt Dispensing System is the workhorse of the LA4050B Labelling Systems, capable of Printing and Application throughput up to 250 labels per minute (dependant on label size). The LA4050B EB is capable of applying labels to side, top or bottom of products. It is also able to provide wraparound label solutions in conjunction with a secondary wipe down station to achieve higher throughputs than conventional wrap systems.The system is designed for use with a variety of Print Engines such as Sato, Zebra, Datamax etc. in 203dpi and 300dpi Printing Resolutions. Typically used for Top and Side Case Labelling the Weber LA4050B EB can be used in a variety of Industries from Logistics and Warehousing to Food and Beverage.

It is primarily designed with simplicity in mind and provides a robust reliable means of Labelling without the need for air supply like other systems currently on the market. Like all Weber Labelling Systems the unit is modular in design with easy to remove unwinder, rewinder, and Print Engine in the event of a critical component failure. This provides significant benefits for 24/7 operation where downtime is a cost critical factor. The choice of Print Engines add to the versatility of the System and  provides label size ranges from 10mm x 5mm up to 180mm x 800 mm at a speed of up to 250 labels per minute (dependant on label size). The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The basic controller can manage the functions of the Labelling System with ease and simple to use menus.

provides label size ranges from 10mm x 5mm up to 180mm x 800 mm at a speed of up to 250 labels per minute (dependant on label size). The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The basic controller can manage the functions of the Labelling System with ease and simple to use menus.

The system has a pivoting U-Arm which allows rotation of the system by 360 degrees allowing the Labelling System to Print and Apply a label to any side of a product including Base Labelling of Products. The system can be mounted on its own individual stand, integrated directly into a packaging machine as part of an automated packaging line or mounted directly on one of our many handling systems providing a turn key solution to your particular Labelling requirements.

Other Benefits include:

- Low Total Cost of Ownership

- High accuracy Labelling

- Versatility and Flexibility in Labelling Configuration

- Easily adaptable to changes in Production

- Low Running Costs (no compressed air required)

- RFID Upgradeable

- High Throughput 24 / 7 Operation

- Available in 4″ wide and 6″ Wide Print Widths

Additional Options include:

- Low label Warning System

- Protective Enclosure for Harsh Environments

- Barcode Scanning Module

- RFID Print Engine

- Vision System

- Choice of Product Detection Sensors

- Bespoke Handling Systems available

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

LPA_TIN_063D_LA_4050B_EB_GBSATO CG Series

With superior performance and affordable price, these 2″ or 4″, 203 or 305 dpi, Direct Thermal/Thermal Transfer printers are best in their class. The SATO CG Series models are delivered stock out of the box with competitive emulations onboard and optimal interfaces (built in USB standard) for outstanding performance in clinical and processing environments. […]

View ProductAxicon 7015 Barcode Verifier

The Axicon 7015 combines CCD based hardware and state of the art application software, conforming to the latest ISO/ANSI print quality standards (ANSI x3.182 and ISO/IEC15416-1). Our equipment has been independently tested and conforms to ISO/IEC15426-1. The Axicon 7015 is designed for all barcodes where an 8, 10 or 20mil aperture is mandatory (such as GS1-128 and ITF-14), up to 195mm width including quiet zones. The simple to use design reduces user error and eliminates product damage whilst providing the highest level of accuracy achievable for verification.

View ProductTest Sub Category

Test

View ProductGeset Labelling Machine

Fast, reliable, economical solutions to product labelling: Geset 100, 300 and 700 labelling machines are part of a modular system. Up to 50 modules are available for design solutions to customer demands. The Geset 100 is a labelling machine for small production series, designed to produce small volumes as accurately and flexibly as would a large plant. Its robust construction renders it ideal both for intermittent use of only a few minutes per day and for multiple shift operation.

View Product