Working Apps’ Tray Trace

Summary

Tray Trace is the effective answer to the management of re-useable containers. With the use of unique identifiers for each tray, container, roll cage, IBC, transit tank, barrel, gas bottle, potato box or pallet means these can be scanned on delivery, collection and at base to provide an accurate record of the container’s use and current location. Re-usable containers are environmentally friendly if re-used; where are they going to, and who is losing and not re-using costs a business both monetarily but also in loss of resources. Further Tray Trace lets you record the condition of the container, its temperature and free text as an option.

Description

Tray Trace has been designed to be flexible so that the application can be simply tailored to the customer’s requirements. 2D barcodes are recommended for their durability, but 1D will also work.

The user signs on either using a user name or as a vehicle run.

The user once signed on; can deliver, collect or check trays by scanning unique barcodes on the trays. Optionally Tray Trace lets the user record the condition of the tray as a drop down list, and or other factors such as temperature, as well as a free comment field.

On collection the tray returns to the user or route, optionally recording the condition.

A full stock check of trays at depot can be made, or a single check for its location.

The output is a list of trays their location and optionally condition, so that the owner knows where the re-usable containers are “resting”, and if required who to call to get them back.

Languages

- English

![]()

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

- Print and apply labels on a production line in one easy step

- Choose from a wide range of 203, 300 and 600-dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor the operation via a web browser

- Available with RFID capability

Model 5300 Series Direct-Tamp Label Printer-Applicator

This Weber exclusive Model 5300 label printer application system provides high-resolution printing and high-speed operation combined with the dependable direct tamp method of label application. This method is similar to tamp-blow, but the flexible tamp pad makes direct contact with the product during application.

View Product

Zebra 105SL Plus

Economical, dependable, high-performance printing Zebra’s 105SLPlus printer provides economical, dependable, high- performance printing. This rugged printer is built for continuous operation, with exactly the features needed for fast, reliable and cost-effective printing in your manufacturing and warehousing environments. The 105SLPlus printer leverages Zebra’s proven electronics platform to offer increased speed for high-volume applications – and […]

View ProductMarkoprint Shutter Printhead HP

Inkjet nozzles can clog and dry up in a dusty printing environment, which is typical in wood-processing enterprises and other sectors. This results in poorly printed images. Our Markoprint Shutter Printhead HP prevents dust from entering the ink cartridge or gathering on the nozzles. During a production halt, the printhead automatically retracts the cartridge and shuts the open nozzle plate. After being paused for even several days, it is instantly ready to print again.

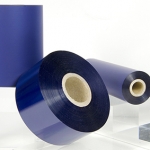

View ProductArmor AWR470 Thermal Transfer Wax Ribbon

AWR®470 SolFree® is the only ribbon in the world to be coated without using solvents, including for the backcoating. SolFree® represents a saving of 365g of CO2 compared to the same ribbon (with average dimensions) produced with a traditional process for the backcoating. AWR®470 SolFree® is well known for its high coverage ability which is essential for printing the rough materials widely used in logistics.

View Product