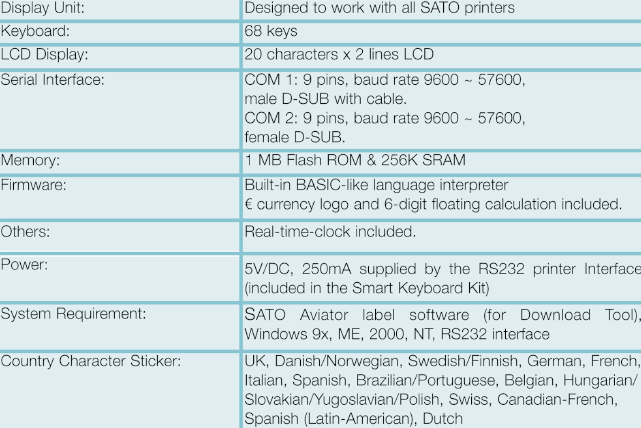

SATO DS Keyboard

The clever and compact SATO Smart Keyboard enables you to use your label printer independent from computers or networks.

Either produce your labels direct, with the Smart Keyboard, or even easier, save your labels designed in SATO Dynamic Aviator or Dynamic Publisher direct in the memory of the keyboard, using the Downloader tool. The intelligent SATO Smart Keyboard is the perfect answer for real stand-alone label production.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

DS-keyboard- Semiconductor / Electronics

- Dual LAN System

- Fastest in the Market

- Large LCD Display

- Easy to Navigate Menu

- User Configurable Print Head

- RFID Ready and Upgradeable

- No PC Required

- Tri-Interface Port

- Built to Last

Furniture Polish Labels

When creating a family of furniture care products such as conditioners and oils, be sure to let the customer see exactly what they will be putting on their expensive wooden treasures. By using clear labels and containers, the buyer can see the products inside, showing your quality ingredients. And since your customer will be concerned about the ingredients, your label needs to show caution information and detailed instructions.

View ProductEpson GP-C831 Printer

Our newly developed printhead protection system protects the ink head from dust to ensure reliable, continuous printing. In addition, Epson’s advanced DURA Brite pigment inks deliver outstanding stability and resistance to water, chemicals, fading and smudges. KEY FEATURES GHS label printer Ideal for large labels including large format drum and chemical labeling BS5609 certified Complies […]

View ProductSato GT4e High Performance Industrial Printing

FEATURES

Markoprint X1JET HP HandHold

The Markoprint X1JET HP HandHold inkjet printer is a versatile, mobile, industrial, small character inkjet printer. The X1JET HP HandHold is battery operated and will print high resolution text and images without being fixed to a production line. The long-life battery allows you to print over an extended period of time. Configuring the device and uploading of print images is a simple task using a USB stick and the Markoprint iDesign software.

View Product