What happens in 3D printing is that in the future there will be not only “4D printing” , which can change 3D-printed objects with time. Soon, it will also be possible to use erasable ink for 3D printing.

Deleteable ink in 3D printing

The talk is of the 3D printing process by “direct laser writing”. Micrometer-small structures with precisely defined properties can be written. Like a pen, a computer-controlled, focused laser beam creates a structure in a photolack. Researchers from the Karlsruhe Institute of Technology (KIT) have developed an ink with a reversible binding linkage, the building blocks of which can be separated from one another – virtually an ink with break-in points. The print is deleted by dipping it into a solution chemical. At the erased location again can be written again, so that the structure can be changed several times.

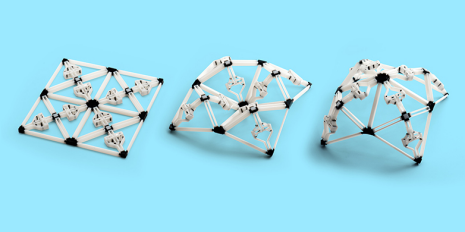

Why? For supporting constructions, for example – similar to bridge construction: when using erasable and non-erasable inks in 3D printing of an object in combination, certain supporting scaffolds could be produced within this object, which can be “erased” with the aid of a special chemical, left. This would be interesting, for example, in material development.

For applications in biology, for example, special petrischals could be printed with the erasable ink in which cell cultures could grow in a suitable spatial structure. In order to investigate how the cells react to altered environments during growth, parts of the three-dimensional microstructure could be removed after a while.

It would also be conceivable to produce reversible wire bonds as electronic components with the help of erasably written conducting structures. The mixing of a permanent and a nonpermanent ink can also influence the properties of the printed material and make it, for example, more or less porous.