Tamper Evident

Weber’s Tamper Evident OEM module is specifically designed to fit neatly into existing Serialisation or Pharma Packaging Systems.

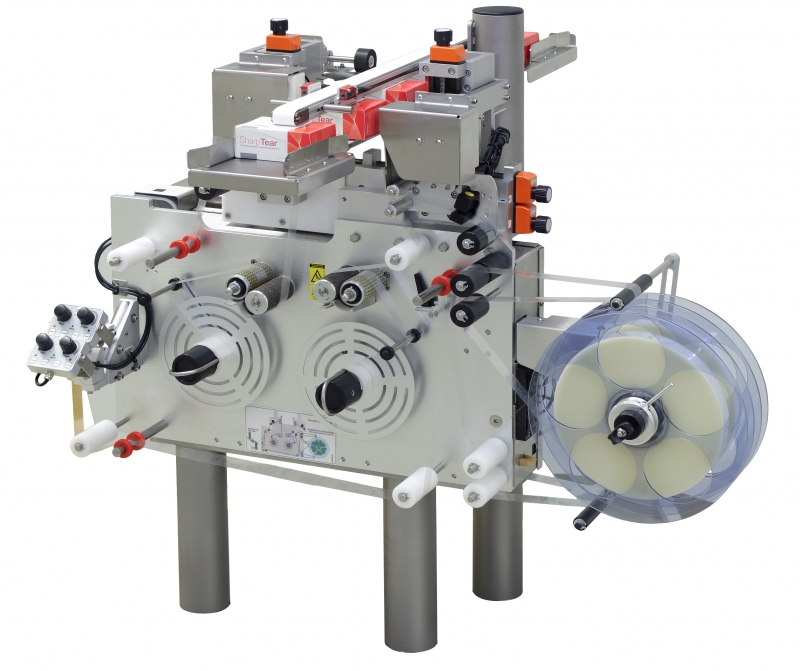

Tamper Evident Labelling Module

The EU Directive 2011/62/EU introduced legal framework requirements for a pan-European safety system for prevention of counterfeit medicines. A central component, which is also addressed in the pharmaceutical law, is a clear and secure marking system for database-backed traceability and tamper-proof sealing of all packaging. Weber can offer a compact, efficient and reliable solution to this requirement. A compact labelling unit is integrated into existing or newly configured Pharma Packaging Systems. A tamper evident label is applied to each end of the carton providing a secure seal which is checked by sensors. The data from all correctly serialized cartons is memorized using the track and trace software allowing each unique pack to be traced back to the manufacturer at any point in the supply chain.

Each individual carton is printed with a unique identity and 2D matrix code produced by sophisitcated track and trace software, which is linked to a vision system. In the event that the vision system detects a mis coded product the system can be configured for use with a Reject Station to dispose of the product.

As this solution is specifically designed for OEM Integration it has a small footprint for ease of installation and configuration. Maintenance and Label Reel change downtime is minimised due to the specific design of the system.

Special Features

- Sealing labelling for protection against counterfeits

- Two-sided corner labelling of folding boxes

- Highly compact design to allow integration into existing plant

- Output clocking up to 300 items per minute

- Stepper motor driven applicator

- Short set-up times when switching to other product formats

- Processing of transparent, perforated labels

- Speed-independent labelling via Tamp-Wipe-On method

- Dual label roll unwinding

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Manufacturing- Label and Wristband Printing

- High Speed Printing

- Printing Resolution of 203 / 305 / 609 dpi

- Anti-microbial Casing

- Small, Compact, High

- Throughput Design

- Easy Media Loading and Maintenance

- Wireless Connectivity

- RFID Ready

-

-

- Applies label up to 6″ high x 12″ long

-

-

-

- Handles up to 45 products/minute

-

-

-

- Placement accuracy of 0.03″

-

Sato CT4i Compact and Versatile Printer

FEATURES

Labelling Applicator Options

Weber Label applicators offer numerous labelling options: Change of format The label dispensing head is quick to replace (approx. 30 seconds), with our optional Quick-Change system. This means that our label printing dispensers are equipped for the most varied of present and future labelling requirements – a system for many applications. Labelling from all sides […]

View ProductSolicom ClockInOut

Summary

Solicom ClockInOut is an easy to use application, with just a single screen showing the current time and after scanning a badge, a welcome or goodbye message is shown for the person just scanned. Badges that are allowed for entrance can be put in a lookup table. All badges scanned are saved in a report table. Via a supervisor menu, activated by a configurable special badge number, the download and upload of both tables can be controlled.

View ProductWeber 114 One-Sided/Two-Sided Labelling System

The brand-new Weber 114 system provides a simple, cost-effective solution to low volume labelling for applying labels to one or two sides of a straight-walled product or package. The Model 114 can be added to in-place production lines or operated manually as a stand-alone applicator.

The Weber 114 is easy to use and can be set-up quickly. During application, labels are peeled away from the liner and securely attached to products using the wipe-on label applicators.

The unit boasts robust steel construction making it perfect for lower-volume, intermittent labelling projects or multiple-shift larger-scale operations. This is a very reliable wipe-on application system that is built to last.

View Product