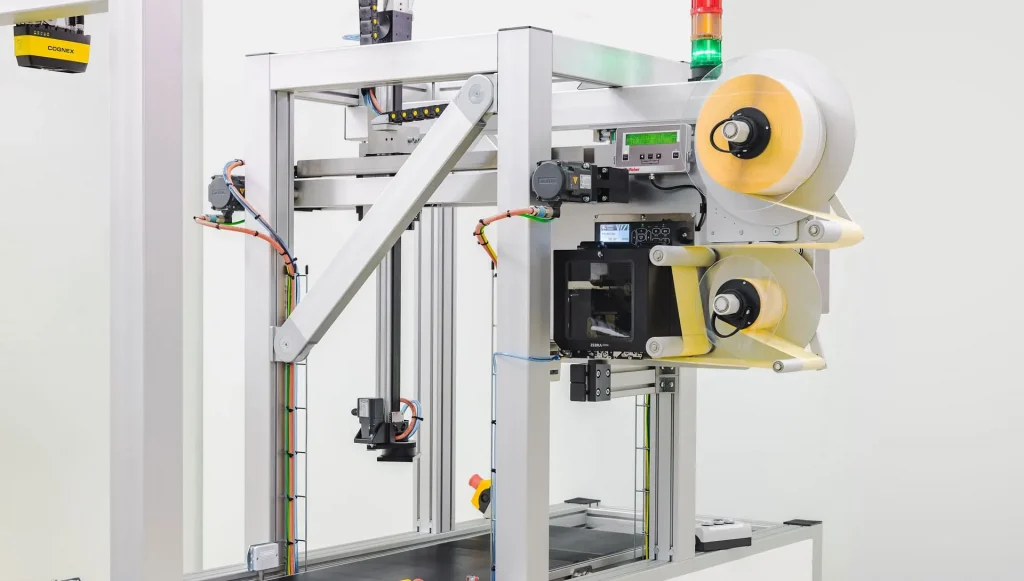

Weber Legi-Flex 6100 Label Print & Apply

With unprecedented demand on supply chain, the impact on companies warehouse and logistics processes are greater than ever. The need for automation is something that all businesses need to consider. The all new Weber Legi-Flex 6100 is a revolutionary new design that addresses the automation needs of businesses particularly in relation to the handling and labelling of products.

The Legi-Flex 6100 builds on the proven labelling technology of our LA4050 series but with a new “3D Label Application Module”. Traditionally, labelling systems label products in a fixed position as they are transported on a conveyor belt and requires alignment or product positioning guidance. The Legi-Flex 6100’s ground-breaking sensor technology recognises the position of each box and automatically adjusts itself to label the product in the correct position with pinpoint accuracy.

The Legi-Flex 6100 can automatically print and apply labels to a wide variety of packages and containers of varying shapes and sizes, and similar to all Weber Labelling Systems, is easy to integrate into existing packaging lines or as a standalone solution. What is most notable feature of the Legi-Air Flex 6100 is the “3D Labelling Module” . This means the Legi-Flex 6100 can support only one single Labelling System per line unlike traditional labelling systems that require additional labelling systems for each labelling position.

Key features:

-

- Minimal Downtime for Label Reel Replacement or Servicing

-

- Wide Variety of Label shapes and sizes catered for including, non batched products

-

- Innovative “3D Labelling System” concept

-

- Designed and built by Weber Packaging Solutions

-

- Enhanced Connectivity – Onboard IOT

-

- Choice of Print Engines to suit your existing configuration

-

- Modular Design – Rewind, Unwind, Applicator, Print Engine

-

- Full Range of 24/7 Remote or Onsite Support Services

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Weber LA4050I – Industrial Printer Applicator

Based on a modular construction the Weber LA4050I is the Industrial version of our proven Weber LA4040E Standalone Labelling System. The system has all the features and benefits of the 4050E, capable of numerous methods to print and apply a label. The design comprises a feeder module, a printing module, label winder and unwinder with numerous applicator types. The standard Tamp-Blow system has a quick-change system for changing the tamp pad which significantly reduces the changeover time to other label formats. The entire system is encased in an Industrial Cabinet suitable for harsh Production or Warehouse environments.

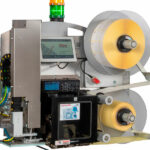

View ProductWeber Legi-Air 4050E Generation 3 Print Apply System

The Weber Legi-Air 4050E Generation 3 is the latest offering by Weber Packaging Solutions of the 4050 Labelling Systems range. It has the reliability and modularity of its predecessor the LA4050E Version 2 but with on board Intelligence and an enhanced User Interface. In the design of this system Weber has focused on reliability, connectivity, efficiency, and versatility.

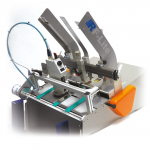

View ProductGeset 125 Horizontal Labelling System

The Geset 125 labelling system is used to label cylindrical products automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage of the labelling system. Care should be taken on accurate alignment of the products between the two freely mounted rollers of the roll conveyor. The side guide’s position the products flush with the outside edge of the roll conveyor.

The roll conveyor feeds the products to the labeller. There the label is applied with the part running forward onto the product and it is pushed by rotation and the back pressure of the wrapping unit onto the product. The back pressure of the wrapping unit (the speed of the wrapping unit is twice as fast as the speed of the base conveyor) enables the product in rotation. The roll conveyor forwards the finished labelled products to the outfeed. Here the products are removed manually or by the customer’s conveying system.

View ProductRF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

View Product