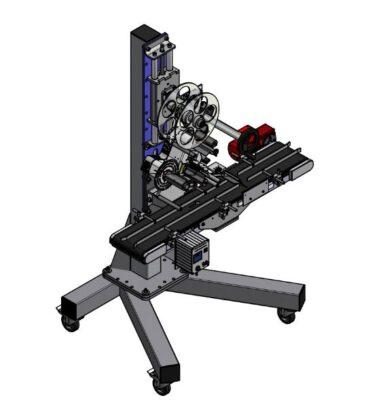

Geset 111 Top Labelling System

The Geset 111 labelling system is used to label square products on the top side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the barrier is reached, an application trigger is tripped. The label applicator applies a label on the product in Wipe On procedure. The label on the top side is pushed on to the product by a brush or roller. After labelling, the products move on and can be removed from the conveyor by the customer.

-

-

- Labelling at top side of square products.

-

- Systems on rolls.

-

- Robust steel base frame.

-

- Simple unmistakable operation by buttons.

-

- Speed of base conveyor can be adjusted by frequency converter.

-

- Proven and reliable applicator technique provided by Alpha Compact, 120mmlabel width.

-

- Performances of up to 100 products per minute are possible.

-

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Geset 111 Instruction ManualGeset 111 Technical Information

Geset 111 Computer Assisted Design

- Print and apply labels on a production line in one easy step

- Choose from a wide range of 203, 300 and 600-dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor the operation via a web browser

- Available with RFID capability

- Fast Speed Printing

- Durabilit

- Enduring

- Anti-microbial Casing

- 2-Colour Printing

EasyGo! ToDoCheckList

Summary

Perform your tasks and control the results with this simple but powerful application. Use the sorting areas and groups features to arrange and dispatch tasks to be performed by the operators. Go through work-flows, perform each task and mark the result of finished tasks.

View ProductModel 5300 Series Direct-Tamp Label Printer-Applicator

This Weber exclusive Model 5300 label printer application system provides high-resolution printing and high-speed operation combined with the dependable direct tamp method of label application. This method is similar to tamp-blow, but the flexible tamp pad makes direct contact with the product during application.

View Product

Sato MB2i Printer

FEATURES

Zebra ZXP Series 7 Card Printer

The fast and reliable ZXP Series 7 prints photo-like cards for medium- to high-volume applications – Utilising the latest in card-printing technology, the ZXP Series 7 card printer provides high-quality card printing. The printer delivers fast yet reliable performance whilst offering users exceptional value by lowering the printer’s total cost of ownership. Time after time, it prints sharp vivid cards with precise colour control.

View Product