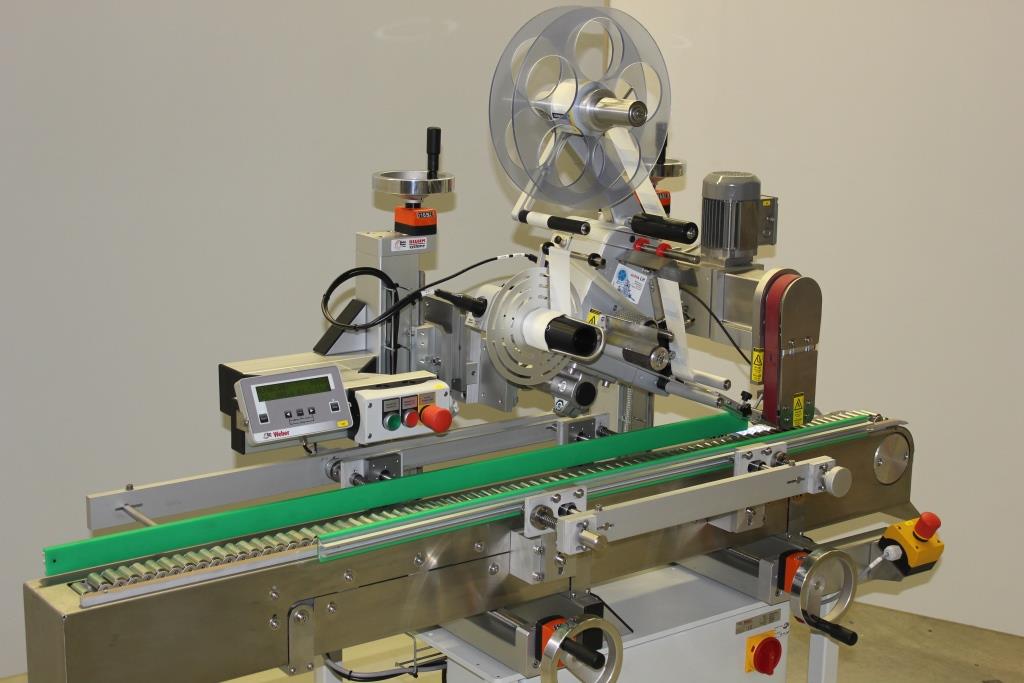

Geset 125 Horizontal Labelling System

The Geset 125 labelling system is used to label cylindrical products automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage of the labelling system. Care should be taken on accurate alignment of the products between the two freely mounted rollers of the roll conveyor. The side guide’s position the products flush with the outside edge of the roll conveyor.

The roll conveyor feeds the products to the labeller. There the label is applied with the part running forward onto the product and it is pushed by rotation and the back pressure of the wrapping unit onto the product. The back pressure of the wrapping unit (the speed of the wrapping unit is twice as fast as the speed of the base conveyor) enables the product in rotation. The roll conveyor forwards the finished labelled products to the outfeed. Here the products are removed manually or by the customer’s conveying system.

-

-

- Wrap-around labelling of unstable, horizontal, cylindrical products

-

- System is standing on rubber feet

-

- Robust steel base frame

-

- Simple, unmistakable operation by push buttons

-

- Speed of base- and wrapping conveyor adjustable by frequency converter

-

- Reliable applicator technique provided by Alpha Compact

-

- Performances of up to 50 products per minute are possible

-

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Geset 125 Instruction ManualGeset 125 Technical Information

Geset 125 Computer Assisted Design

EasyGo! POD

Summary

Manage your deliveries with a simple, customizable and powerful proof of delivery solution. EasyGo! POD has GPS, image capture (requires 2D Imager) and signature support offering true Proof on Delivery as location, product and customer details including the signature are captured. Adding additional comments at the point of activity ensures the highest customer satisfaction. In addition to the delivery registration EasyGo! POD also incorporates the registration process for collecting packages from the costumer site at the very same moment the operator delivers the packages.

View ProductWorkstation Printer

The Workstation is the newest generation of desktop printers from Datamax-O’Neil. These compact desktop printers offer an industry leading design that contribute to its durability while its standard features are similar to those found on the Performance printer line. These features include Ethernet 10/100, 50 resident/scalable fonts, 300 dpi printhead for superior print quality and industry standard PCL5e printer language. The compact design is perfect for environments that require a small footprint and the internal design provides reliable performance and efficient output.

View ProductNAUTIZ X3

POCKET SIZED POWERHOUSE

It’s not one thing that makes the Nautiz X3® a breakthrough in handheld technology – it’s the unbeatable combination of small size, big performance, extreme ruggedness and remarkable value. The Nautiz X3 is like nothing else on the market.

View ProductDNP TR3021, 22, 23 Wax Thermal Transfer Ribbon

Based on DNP’s proven wax technology, these quality ribbons expand your color possibilities while providing excellent print clarity and high smudge resistance when black just isn’t enough. These ribbons are also specially formulated with DNP’s backcoat technology for printhead protection.

View Product