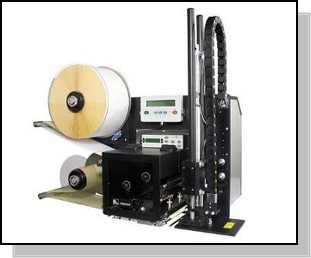

Weber Legi-Air 4050E – Precision Labelling System

Based on a modular construction the Weber 4050E is capable of numerous methods to print and apply a label. The design comprises a feeder module, a printing module, label winder and unwinder with numerous applicator types. The standard Tamp-Blow system has a quick-change system for changing the tamp pad which significantly reduces the changeover time to other label formats.

Weber LA 4050E Modular Labelling System

Our Weber LA4050E print and apply labeller eliminates all the headaches and manual adjustments that cause downtime in the day-to-day operations of a normal labelling system. Designed with all the key components that make a smart, reliable labeller, it has an integrated print engine, with the ability to Direct Apply on-demand labels up to 150 packs per minute with a built in controller with patented technology to precisely and automatically control the entire system. The system prints and applies labels from 10 mm x 5 mm up to 180 x 300 mm with a feeder output of up to 210 labels per minute with our “blow-box” system.

The system is modular in construction to allow flexibility for changes in application or indeed printing technology. The Stroke unit, Print Engine, Unwind and Rewind System are interchangeable and easily replaced which  allows you to make changes to your labelling process quickly and easily and avoiding a complete system replacment.

allows you to make changes to your labelling process quickly and easily and avoiding a complete system replacment.

The system comes with a Pivoting U-Arm which is easily mounted to our System Stand mounting, the system can be rotated 360 degrees in any direction which allows the product to be labelled from any side and in any orientation. A removable display controller supports this flexibility and facilitates simple and quick operation by means of targeted plain text user information and stored system parameters. Flexible control and networking of the system allows integration via a number of interfaces such as Ethernet, serial and parallel data connections as well as USB.

Print Engine Technology

Working closely with all major international print engine manufacturers Weber has designed the LA 4050E with flexibility and localization in mind. Whether Zebra, Sato, Avery, CAB or Datamax-O’Neil is the print engine of the choice, the Weber LA 4050E can accommodate. Where no customer preference is indicated our fully trained, experience and certified Sales staff will recommend the best print engine and application method to suit your individual requirements.

The LA 4050E also can be equipped with an RFID print module that supports existing RFID standards.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

LA4050E_ukOEM Auto Parts Labels

Product ID labels on your OEM auto parts have to last the life of the product. And more than likely, that will be a long, tough life cycle. Weber can help you pick the right materials to ensure that your labels continue to work through all kinds of weather and harsh conditions.

View ProductFunai (Lexmark)

Funai (Lexmark) enables high resolution marking on any surface at very high speed.

Click on the Direct Sales Button, and contact us today to order your Funai (Lexmark) inkjet thermal inks.

View ProductZebra LS4208 – Handheld Scanner

LS4208 handheld laser bar code scanner, you’re able to effortlessly speed throughput, even with bar codes in poor condition. Wherever you need to quickly capture and process data — such as at the retail checkout counter, in pharmacies and hospitals, and in light warehouse environments — this ergonomically designed scanner helps you increase accuracy, improve productivity, cut maintenance

costs and reduce the risk of downtime.

Weber 121 Wrap-Around Label Applicator

Weber’s versatile 121 provides a simple, cost-effective solution to low-volume wrap-around labelling that is as accurate and flexible as similar labelling systems used in larger-scale operations. This labelling system features the fast and accurate positioning of full, overlap and partial-wraps of pressure-sensitive labels on cylindrical containers.

Products up to 7″ in diameter and up to 12″ high easily can be accommodated using the system’s adjustable guide rails. It can handle labels up to 6 inches tall and 12 inches long and apply them at rates up to 45 products per minute to a variety of sized products. During application, labels are peeled away from the liner and securely attached to products using the wipe-on label applicator and a wrap station.

View Product