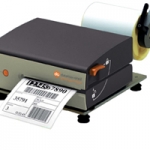

M-Class Mark II

The M-Class is a compact, industrial-strength printer that offers outstanding value with a broad range of features.

The smaller footprint is ideal when users need the power of industrial printers but must consider space limitations. The M-Class has proven to be the perfect solution for warehouse, healthcare, logistics and retail applications. The modular design of the M-Class makes maintenance and part replacement easy, and the flexible design allows for a variety of options to be upgraded in the field.

Specifications at-a-glance:

- Direct thermal, thermal transfer (optional)

- 4.25” [108mm] maximum print width

- 203 dpi [8 dots/mm], 300 dpi [12 dots/mm] optional resolution

- 10 ips [254 mm/s] maximum print speed

- Serial, parallel, USB, LAN (optional), wireless 802.11g (optional)

https://www.youtube.com/watch?v=GvDBtAghRsw

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

M Class MII Printers- Direct thermal

- 203 dpi [8 dots/mm], 300 dpi [12 dots/mm] optional resolution

- 5 ips [125 mm/s] maximum print speed

- 4.1″ [104mm] maximum print width

- Serial, USB, LAN, wireless 802.11b/g with WPA2 security protocol (optional)

- PL-Z, PL-I, and PL-B emulations on the DPL versions

- Printing Labels and bracelets

- Print Resolution 203/305 dpi

- Antimicrobial housing

- Small, compact

- Easy maintenance

Compact 4 Mobile

The Compact4 Mark II mobile printer is designed for installation on conveyors, forklift trucks and mobile stations. It can operate from a connection to a forklift’s battery and its vibration-proof design makes it the perfect choice for warehousing logistics.

Specifications at-a-glance:

Sato CT4i Printer

FEATURES

E-Class Mark III Barcode Printer

The E-Class Mark III is a family of compact desktop thermal printers that are designed for a wide variety of industries and applications that require a reliable and cost effective barcode printer. Datamax-O’Neil applied its industrial printer expertise to provide customers with an entry level printer that has the features and reliability normally found in more expensive printers. The E-Class Mark III is affordable to own, easy to use and economical to operate.

View ProductHand-Held Label Applicators

These light-weight Towa brand label applicators are the fast, easy way to manually apply pressure-sensitive labels, including RFID tags, to your products. They are available in a variety of sizes from 20mm to 100mm in width.

If you need to apply labels to small batches of products or cartons, these Towa hand-held label applicators can help speed up production and accuracy. Just squeeze the lever and labels are advanced for application. Fast and easy labelling!

View Product