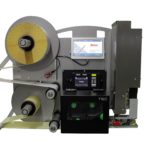

Model 5300 Series Tamp-Blow Label Printer-Applicator

This Weber exclusive provides high-resolution printing and high-speed operation combined with the highly-accurate tamp-blow method of label application. This allows you to add a method of labelling your products quickly and efficiently on your production line.

• Choose from a wide range of 203, 300 and 600 dpi print engines

• Capable of handling print speeds up to 16 ips

• Numerous I/O’s ease interfacing with external devices

• Monitor operation via a web browser

• Available with RFID capability

Model 5300 Series Tamp-Blow Label Printer-Applicator

Weber’s Model 5300 tamp-blow system is redefining the meaning of versatility in pressure-sensitive label printing and application.

In addition to offering a broad selection of high-quality print engines that feature various print resolutions and label dispensing rates, this Model 5300 system is available with optional RFID print-encode engines.

Standard direct and thermal-transfer print engines from manufacturers Zebra, SATO and Datamax produce text, bar codes and graphic images at 203, 300 or 600 dpi. The Zebra-based RFID models combine these printing capabilities with the encoding and verification of RFID inlays to meet EPC Gen 2 protocols.

Special Features & Options

The Model 5300 tamp-blow system includes a number of noteworthy features that add to the operational versatility of this printer-applicator:

• Tamp-blow application: This is a very popular method of air-assisted label placement used with standard applications and is particularly useful in the labelling of recessed areas. A printed label is fed onto a tamp pad and held by vacuum, a pneumatic cylinder extends to within .25 inch of the product, and the label is blown onto its surface to a placement accuracy of 0.03″.

• Browser-based monitoring: The status of all operational functions and configurations can be monitored by logging on to a web page that is unique to each Model 5300 unit.

• Numerous I/O’s: The system can be interfaced with many types of external devices.

• One-to-one media consumption: Special label unwind and rewind dimensions are matched to the system’s ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers.

• Print job storage: Multiple label printing formats can be stored in the system’s memory, making it easier for an operator to select a job directly from the applicator instead of downloading a computer file.

The Model 5300 tamp-blow system boasts numerous additional features, including an upgradeable microprocessor controller, various inputs/outputs, plus durable construction that will withstand harsh industrial environments.

There also are several optional enhancements that can increase the system’s functionality. A product height sensor, for example, enables the printer-applicator to label items of varying heights delivered by the same conveyor.

Other options include a 15-foot umbilical connection that enables the remote location of the unit’s controller; an adjustable stand for optimum system orientation; label-on-pad and product-presence sensors; plus beacon light alerts to signal the status of label and ribbon supplies.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

5300Zebra LI4278 Bar Code Scanner

The LI4278 takes 1D bar code scanning to the next level, allowing workers to scan faster and farther. Workers can capture virtually any 1D bar code, including the typical bar codes that are printed on paper labels; electronic bar codes displayed on the screen of a mobile phone, tablet or computer that allows retailers to easily process loyalty cards, mobile coupons and more; and the high density (HD) bar codes commonly used in electronic component manufacturing. 100 percent UPC bar codes can be captured from near contact to over 30 in./76.2 cm away, while 200% UPC codes can be scanned at 55 in./139.7 cm away.

View ProductEpson GP-C831 Printer

Our newly developed printhead protection system protects the ink head from dust to ensure reliable, continuous printing. In addition, Epson’s advanced DURA Brite pigment inks deliver outstanding stability and resistance to water, chemicals, fading and smudges. KEY FEATURES GHS label printer Ideal for large labels including large format drum and chemical labeling BS5609 certified Complies […]

View ProductLegi-Air 5300 Tyre Label Printer-Applicator

According to an EU regulation all new tires produced in or after January 2012 and placed on the market within the EU must bear a standardized EU sticker, such as those already seen on washing machines and refrigerators. The new label must contain precise details with seven grades (A-G) of fuel efficiency, wet grip, and exterior noise when in motion (in dB), respectively.

View ProductWeber LA4050B-EL – All Electric Linear Print Apply System

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

View Product