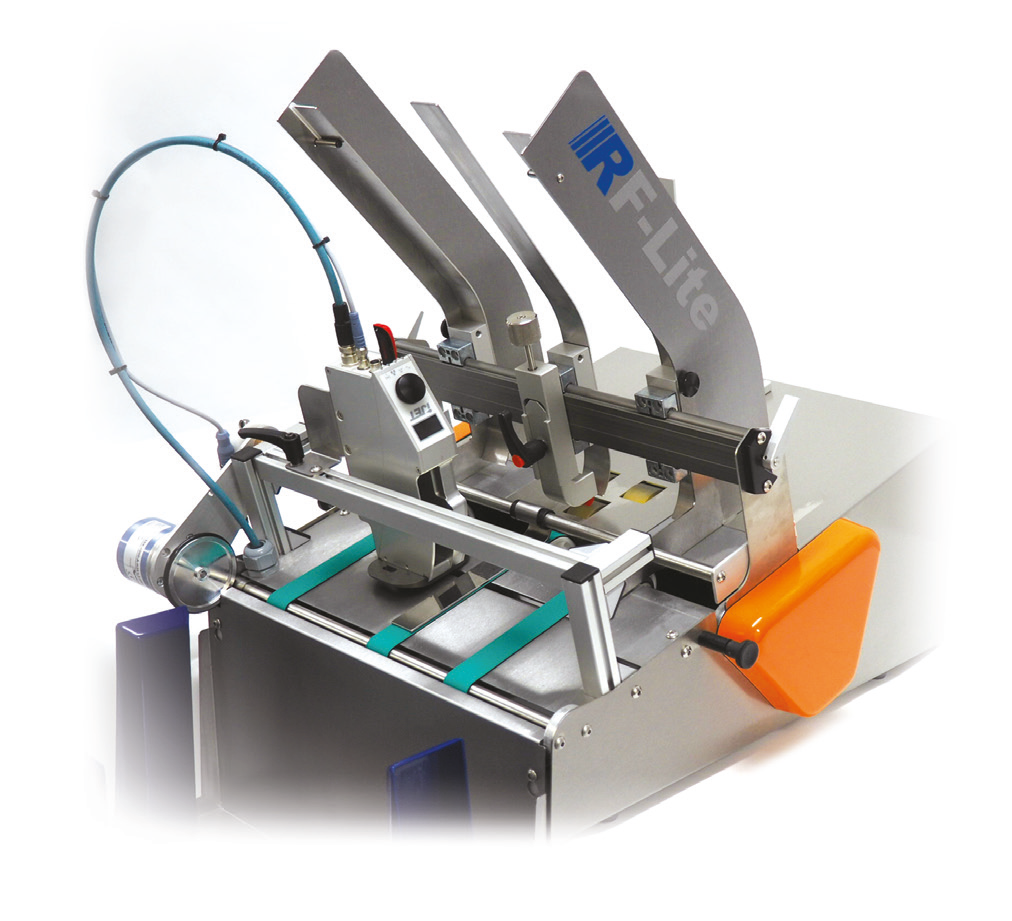

RF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

The RF-Lite is a simple, low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time. It also suits larger operators who are looking to install dedicated marking systems on multiple production lines.

RIGHT CODE

Fitted with clean, thermal inkjet technology, the RF-Lite is ideal for printing

clear, concise date and batch codes onto sleeves and cartons.

RIGHT PLACE

The RF-Lite can consistently print codes onto all shapes and sizes of sleeve ranging

from 30 x 70mm to 300 x 200mm. It only takes a few seconds to swap between sizes.

RIGHT COST

With its comparatively low upfront cost, the RF-Lite is an ideal entry-level solution for companies wanting to automate their offline date coding.

“This compact unithas dramatically reduced

the time taken to codeour cartons.”

OTHER BENEFITS

• It’s easy to set up and adjust; no training needed.

• The RF-Lite’s tiny 500 x 500mm footprint means that it can be easily squeezed into tight spaces

• We offer a money-back guarantee if the system does not meet the customers needs and expectations*

• Under our one-year warranty we can replace a broken down RF-Lite unit within 24 hours*

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

RF-LiteDNP TR3021, 22, 23 Wax Thermal Transfer Ribbon

Based on DNP’s proven wax technology, these quality ribbons expand your color possibilities while providing excellent print clarity and high smudge resistance when black just isn’t enough. These ribbons are also specially formulated with DNP’s backcoat technology for printhead protection.

View ProductNAUTIZ X4

WORK-READY, FIELD-TOUGH

Merging ultimate mobility with true field functionality, the Nautiz X4 rugged handheld is a durable tool designed with fieldwork in mind — it’s packed with features, it’s compact and truly portable, and it offers a reliable computing solution for challenging worksite environments.

View ProductElectronic Hand Held Label Applicator Model LD 70

Used directly from it’s own mains power supply or remotely from it’s rechargeable batteries, the LD70 can dispense and apply labels up to 65mm wide and there is no restriction on the maximum length.

View ProductTamper Evident Label Applicator

A core requirement of the European Directive 2011/62/EU that will come into force by 2016 is to equip the outer packaging of medicals with a tamper evident feature. Which should ensure the customer that he is the first opening the package.

View Product