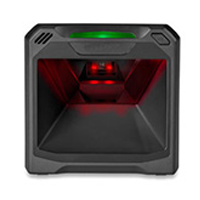

Symbol DS7708 Scanner

Easy to Deploy, High-Performance, “Can’t Miss” On-Counter Scanning

When it comes to on-counter scanning, the DS7708 scanner offers a feature set that puts it at the top of its class for performance, ease of use, easy deployment and total cost of ownership. With a large field of view that is over 50 percent larger than the competition, the DS7708 easily captures bar codes regardless of where they are located on an item. No matter what type of bar codes appear at the POS, the DS7708 can scan them all: 1D, 2D, printed and electronic.

Innovative Features of the DS7708 Scanner

Scan virtually any type of bar code

First time, every time capture of 1D and 2D bar codes displayed on mobile devices or printed on paper labels—even if they are damaged, poorly printed, or dirty.

PRZM intelligent imaging

The DS7708 resets the bar for 2D imaging by improving decode performance and snappiness, while dramatically improving user experience, user productivity, throughput and customer wait times.

Largest field of view in its class

A field of view that is over 50 percent larger than competitive 2D imagers enables easy capture of bar codes, regardless of where they are located on an item. Scanning is truly second nature—no need to orient an item to capture the bar code.

Superior durability

Multiple features make the DS7708 the most durable device in its class: the recessed scan window prevents marks and scratches that can degrade scanning performance and lifecycle. In addition, the electronics are located in the top area of the DS7708 to prevent damage and protect uptime in the event of a spill.

Virtually invisible illumination

The LEDs are recessed behind the scan window, where they are barely visible and won’t disturb customers or cashiers.

Power through a single USB port

No additional power supply is required when connecting via USB, reducing accessory, installation and management costs.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

DS7708_SS- Small Footprint

- Lightweight

- Compatible with PDA

- 2-Colour Printing

- Wireless Connectivity

PLUSMARK – Premium Wax

PLUSMARK is the high performance wax ribbon from Weber. It offers all

the benefits of a general purpose wax ribbon with an improved print durability

and a capability to print on synthetic label materials.

Markoprint Integra PP RAZR

Experience Effortless High-Resolution Printing: Introducing the Integra PP RAZR with Cutting-Edge Technology. Print Up to 34mm High on Virtually Any Product Surface with Ease. Be Amazed by the Permanent Print Head’s Impressive Resolution, Lightning-Fast Speed, and Integrated Redundancy. Plus, its Compact Design Ensures Seamless Placement in Any Production Facility.

View ProductZebra ZD410 HC

The ZD410 healthcare model offers all of the features of the standard model plus disinfectant ready plastics and an IEC 60601-1 compliant power supply. Designed for hospital, clinic, laboratory and pharmacy applications, the direct thermal ZD410 helps to protect privacy by leaving no record on a ribbon of what has been printed. The optional 300 dpi print resolution is ideal for printing small labels. The ZD410 healthcare model is currently available for purchase only in North America and the European Union countries. It will be launched in other countries throughout 2016.

View ProductSato MB4i Printer

FEATURES