Tamper Evident

Weber’s Tamper Evident OEM module is specifically designed to fit neatly into existing Serialisation or Pharma Packaging Systems.

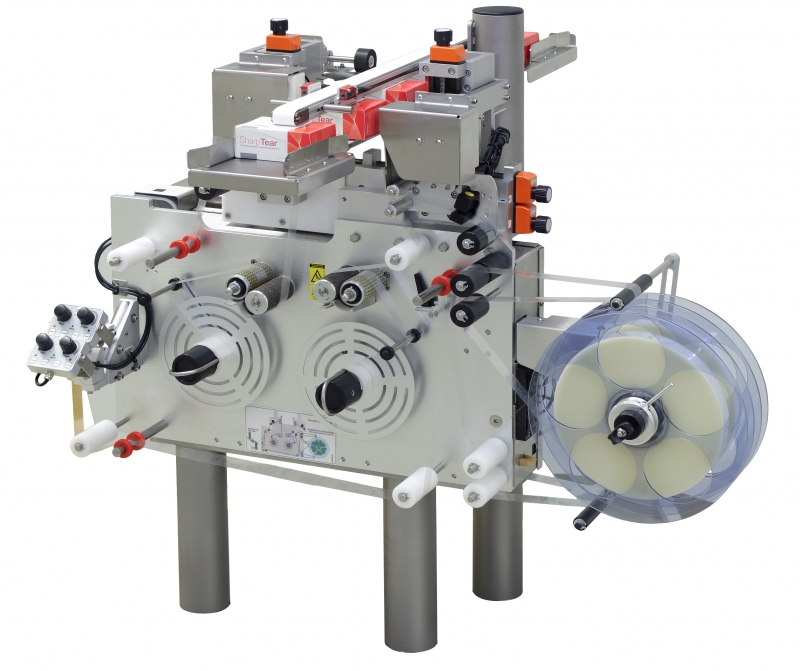

Tamper Evident Labelling Module

The EU Directive 2011/62/EU introduced legal framework requirements for a pan-European safety system for prevention of counterfeit medicines. A central component, which is also addressed in the pharmaceutical law, is a clear and secure marking system for database-backed traceability and tamper-proof sealing of all packaging. Weber can offer a compact, efficient and reliable solution to this requirement. A compact labelling unit is integrated into existing or newly configured Pharma Packaging Systems. A tamper evident label is applied to each end of the carton providing a secure seal which is checked by sensors. The data from all correctly serialized cartons is memorized using the track and trace software allowing each unique pack to be traced back to the manufacturer at any point in the supply chain.

Each individual carton is printed with a unique identity and 2D matrix code produced by sophisitcated track and trace software, which is linked to a vision system. In the event that the vision system detects a mis coded product the system can be configured for use with a Reject Station to dispose of the product.

As this solution is specifically designed for OEM Integration it has a small footprint for ease of installation and configuration. Maintenance and Label Reel change downtime is minimised due to the specific design of the system.

Special Features

- Sealing labelling for protection against counterfeits

- Two-sided corner labelling of folding boxes

- Highly compact design to allow integration into existing plant

- Output clocking up to 300 items per minute

- Stepper motor driven applicator

- Short set-up times when switching to other product formats

- Processing of transparent, perforated labels

- Speed-independent labelling via Tamp-Wipe-On method

- Dual label roll unwinding

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

ManufacturingSATO CG Series

With superior performance and affordable price, these 2″ or 4″, 203 or 305 dpi, Direct Thermal/Thermal Transfer printers are best in their class. The SATO CG Series models are delivered stock out of the box with competitive emulations onboard and optimal interfaces (built in USB standard) for outstanding performance in clinical and processing environments. CG2 […]

View ProductMilk Labels

Milk labels come in all shapes, sizes and flavors these days. With all the new types of containers, it is sometimes hard to find the right adhesive to keep your label on your product. We have some great ideas that can help you improve the appearance of your milk brand. Weber can help you pick the right adhesives and facestock to stand up to the refrigerated environment and still look refreshing.

View ProductZebra 105SL Plus

Economical, dependable, high-performance printing Zebra’s 105SLPlus printer provides economical, dependable, high- performance printing. This rugged printer is built for continuous operation, with exactly the features needed for fast, reliable and cost-effective printing in your manufacturing and warehousing environments. The 105SLPlus printer leverages Zebra’s proven electronics platform to offer increased speed for high-volume applications – and […]

View ProductWeber AP182 Pallet Labelling System

The Weber AP182 is the latest offering by Weber Packaging Solutions of the Pallet Labelling Systems range. It has the reliability and modularity of its predecessor the AL180 but with on board Intelligence and an enhanced User Interface. In the design of this system Weber has focused on reliability, connectivity, efficiency, and versatility. The AP182 System is designed to Label up to three sides of a Pallet simultaneously for specialist pallet identification applications.

View Product