Trident

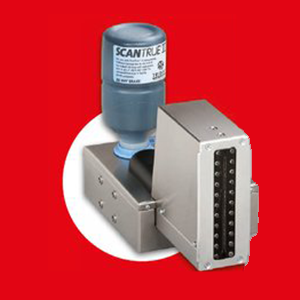

Trident is perfect for text, barcode and graphic marking on absorbent and smooth surfaces.It is easy to use, highly reliable and can reach printing speeds up to 60 meters per minute.

Click on the Direct Sales Button, and contact us today to order your Trident inkjet thermal inks.

- High reliability

Piezo-controlled graphic printing for industry-standard fonts, with almost unlimited number of rows.

- high printing speeds in barcode quality

up to 60 m/minute at 192 dpi (maximum 200 m/minute)

- good print image

based on perfected and proven Piezo technology

- simple operation

through integrated maintenance module

- unique flexibility

through the use of several Trident printheads

- Maximum 50 mm to 800 mm printing heights possible, as well as freely configurable layouts

- Multi-sided coding of packaging on two sides (top, side or at different production lines)

- virtually any porous surfaces can be marked, depending on ink type

- Topping up ink whilst in operation

- up to 5 mm distance from printhead to product surface enables marking of cartons with surface tolerances

- highly economical

- Best price-performance ratio in terms of ratio: cost of ink to area printed

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Weber LA 6000 Labelling System

High Performance Labelling System for Warehouse & Logistics

Modularity, High Performance necessary for Warehouse and Logistics System Solutions

View ProductModel 5300 Series Pail/Drum Label Printer-Applicator

The fully-automatic system that quickly and accurately prints and applies labels to pails or drums on the production line.

• Fully automatic pail/drum labelling system

• Ideal for rough production conditions

• High-grade label printing in a single operation

• Prints and applies labels up to 7″ x 14″

• Labels up to 30 products per minute

• Print resolution up to 600 dpi

• All conventional data interfaces

• Service interval display

• Display controller for simple operation

• Easy integration

• CE certification

Model 4300e Pro-Apply All-Electric Label Printer-Applicator

Weber’s economical Model 4300e Pro-Apply is an electrically-operated printer-applicator that features the functionality often limited to higher-duty pneumatic systems.

The result is a versatile in-line system that combines high-quality label printing and application that ensures fast, accurate pressure-sensitive labelling – and now it’s available without the need to use externally-supplied compressed air.

• Applies labels up to 6″ wide x 6″ long at up to 12 ips

• Prints text, bar codes and graphic images @ 203, 300 or 600 dpi

• Direct-tamp label application

• Accurate labeling to within ±0.03″

Midrange Label Printers

Industrial labels are high-performance products for a broad range of business branches. They can be seen on everything, from beverage packaging, ink cartridges to automotive tyres. In production, logistics, stocktaking as well as trading, these symbols assist to deliver data and supporting advertising

View Product