XB4Jet/XB8Jet

The compact and robust controllers XB4JET and XB8JET are used to control the inkjet printheads for product marking solutions. The following Markoprint printing technologies are supported: Hewlett-Packard, Funai, Trident.

- Simultaneous marking of primary and secondary packaging using a controller

- Printing on up to two production lines with the XB4JET and up to four production lines with the XB8JET

- Perfect for fixed installation in control cabinets as it offers full remote control capabilities through different interfaces

- Print layout can be designed using the iDesign software included in the scope of delivery

- Print layouts are sent to the XB4JET and XB8JET using the network connection, EIA232, USB interface or a USB stick

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

XB4JETXB8JET

- Depth – No Maximum

- Max. Reel Diameter – Max. 225mm

- Core Size – Min. 25mm Ideal 76mm

Working Apps’ Tray Trace

Summary

Tray Trace is the effective answer to the management of re-useable containers. With the use of unique identifiers for each tray, container, roll cage, IBC, transit tank, barrel, gas bottle, potato box or pallet means these can be scanned on delivery, collection and at base to provide an accurate record of the container’s use and current location. Re-usable containers are environmentally friendly if re-used; where are they going to, and who is losing and not re-using costs a business both monetarily but also in loss of resources. Further Tray Trace lets you record the condition of the container, its temperature and free text as an option.

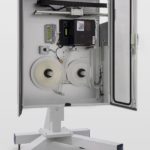

View ProductWeber LA4050I – Industrial Printer Applicator

Based on a modular construction the Weber LA4050I is the Industrial version of our proven Weber LA4040E Standalone Labelling System. The system has all the features and benefits of the 4050E, capable of numerous methods to print and apply a label. The design comprises a feeder module, a printing module, label winder and unwinder with numerous applicator types. The standard Tamp-Blow system has a quick-change system for changing the tamp pad which significantly reduces the changeover time to other label formats. The entire system is encased in an Industrial Cabinet suitable for harsh Production or Warehouse environments.

View ProductRetail Software

Retail Mobile Solutions Whether you are looking for an online, fully integrated solution or a simple office solution, Weber makes moving to a modern mobile logistic and sales-assistant solution easy. The retail software solution gives your stores new and more efficient ways handle logistics and support your customers shopping. Retail Mobile Logistics Solutions Inventrory […]

View ProductElectric Semi-Automatic Label Dispensers

These machines can dispense up to a maximum web width of 152mm butt cut or die cut and adjustments for different size labels are made easily

and without the need for tools.

View Product